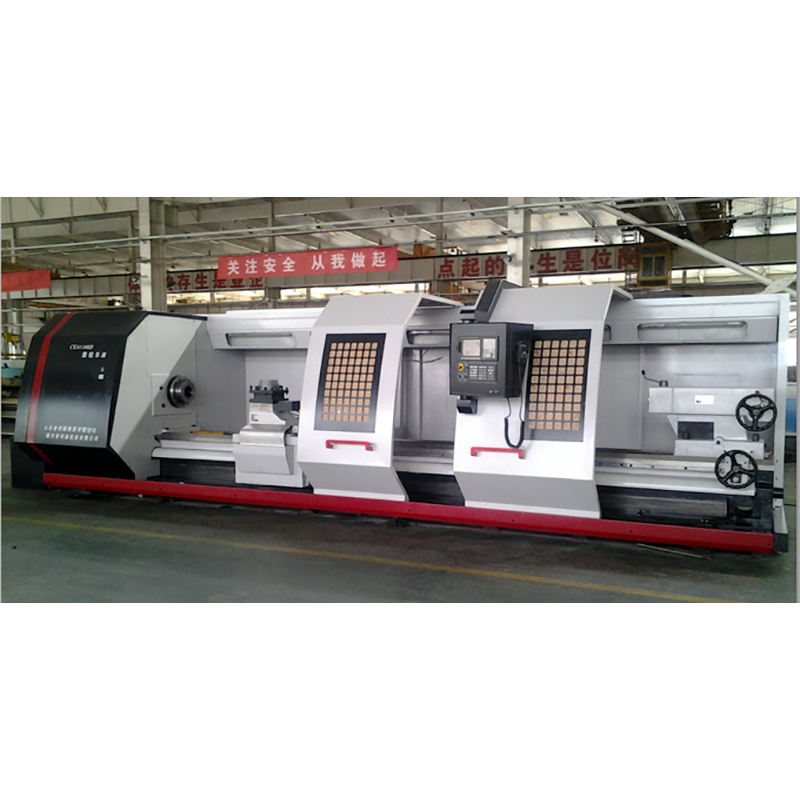

Isikhungo sokujika se-CH61200L CNC esine-eksisi ye-C

Isiyalezo esifushane

Lo mshini uhlanganiswe ne-axis ye-C, i-feed X kanye ne-axis ye-Z, ama-eksisi amathathu angaxhunyaniswa futhi ahambe ndawonye ngokusebenza okuningi nokusebenza kahle kokusika okuphezulu.

Ihlanganiswe nesistimu ye-SIEMENS 828D CNC.

Amagiya amabili esivinini sokuphotha, kanye nesivinini esinganyatheli ngaphakathi kwamagiya, ukushintshwa kwegiya le-hydraulic, ukusika kwesivinini somugqa okungaguquki.Injini yokuphotha eyinhloko i-SIEMENS 37KW AC servo motor, yehlisa isivinini futhi ikhuphule i-torque ngamagiya, isivinini sokuphotha singu-5-200rpm.

I-axis ye-C ikhonjiswe ngokunemba okuphezulu kwe-AC servo motor, kanye nokukhiya okuzenzakalelayo kwe-hydraulic, nokusebenzisa igridi eyindilinga ukuthola indawo yangempela;I-X axis isebenzisa i-SIEMENS AC servo motor eshayelwa kanye nokunemba okuphezulu kwesikulufa sebhola ukuze ibone ukunyakaza okubheke eceleni, i-axis ye-Z ithatha i-SIEMENS AC servo motor drive high precision worm reducer ukuze ihambe ngobude, yomibili i-X, i-eksisi ye-Z ifakwe igridi yokuthola indawo yangempela, ukulawulwa kweluphu evaliwe, ngokunemba kokuma okuhle nokuphinda ukunemba kokuma

ukusetshenziswa komshini

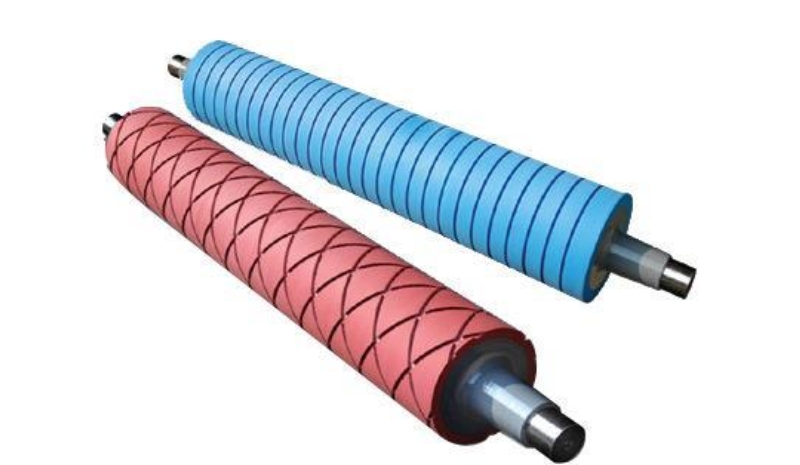

Lona umshini wokusika osebenza kahle kakhulu, ofanele ukusika insimbi yensimbi, insimbi kanye nokucubungula insimbi engeyona insimbi ngensimbi enesivinini esikhulu kanye nethuluzi eliqinile le-alloy.Kungaba ukujika umbuthano wangaphandle, ubuso bokuphela, ukusika umsele, ukusika, ukusika imbobo yangaphakathi, ukhiye wokugaya, umsele ovunguzayo wokugaya, ukubhola nokuthinta.

Imephu edwetshiwe ye-workpiece:

Ukhiye wokugaya

Intambo yokugaya ngokushintsha iphimbo

I-Milling spiral groove, iphethini yesikali

ipharamitha namandla

| Ububanzi bendlela yomhlahlandlela | 1100mm |

| Ubukhulu.swing ububanzi phezu kombhede | φ2040mm |

| Ubukhulu.swayipha ububanzi phezu kokuthunyelwe kwethuluzi | φ1500mm |

| Ubukhulu.ubude be-workpiece | 12000mm |

| Ubukhulu.Isisindo se-workpiece phakathi kwesikhungo | 10T |

| ukudluliselwa okuyinhloko | |

| Ukuthwala kwangaphambili kwe-spindle | φ220mm |

| Ibanga lejubane le-spindle | 5-200r/min |

| Ububanzi be-spindle bore | φ130 mm |

| I-taper yangaphambili yembobo yokuphotha | imethrikhi No.140 |

| Amandla amakhulu emoto, i-servo motor | 37KW |

| Ukucaciswa.yokuphela kwe-spindle | 1:30 |

| ukudluliswa kwesiphakeli | |

| Uhambo lwe-X eksisi | 85 mm |

| z ukuhamba eksisi | 11800 mm |

| isivinini sokuhamba esisheshayo se-x eksisi | 4m/min |

| z isivinini sokuhamba esisheshayo | 4m/min |

| I-Servo motor torque od x eksisi | 27nm |

| I-Servo motor torque od z eksisi | 36Nm |

| I-Horizontal 8 position power turret | 0.5.473.532.8 |

| Usayizi wesigaba se-shank yamathuluzi | 32mmx32mm |

| I-Tailstock | |

| Ububanzi be-Quill of tailstock | φ260mm |

| Khipha ukuhamba | 300mm |

| Imbobo ye-taper ye-quill | imethrikhi No.80 |

| Umsizi wokuphumula okuqinile (amasethi ama-2) | |

| Ukuphumula okuqinile okuvaliwe | φ400-φ700mm |

| qhuqha | |

| Imihlathi emine | φ1600mm |

| I-C eksisi | |

| Ubukhulu.i-torque ngaphansi kwesimo esicishiwe | 3000Nm |

| Ukubeka ukunemba kwe-axis C | 36″ |

| Phinda ukunemba kokuma kwe-eksisi C | 18″ |

Isakhiwo esiyinhloko

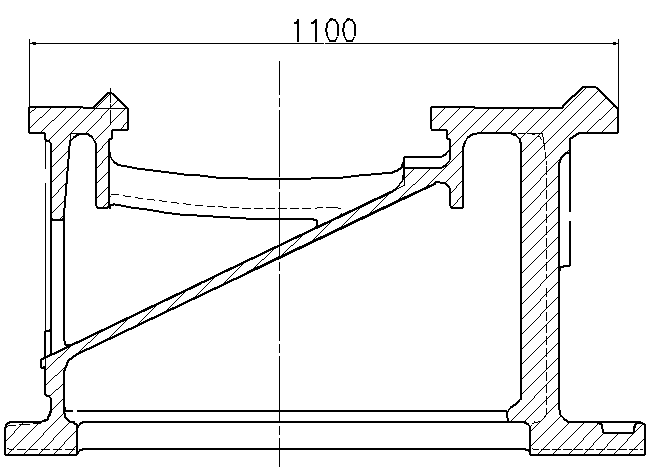

1)umbhede

Umbhede uwumbhede wohlobo lwaphansi onobubanzi obuyi-1100mm kanye nokusakazwa kwesihlabathi se-resin enamandla kakhulu.Impahla yi-HT300.Umbhede unezinzuzo zokuqina okuqinile, umthamo omkhulu wokuthwala nokuzinza okuhle

Indlela eqondisayo iyintaba eyodwa kanye nesakhiwo esisodwa esiyisicaba, ubulukhuni bendlela yokuqondisa bungaphezu kwe-HRC52, ukujula kokuqina okuqinile kuyasiza ukuba phansi.

Ingaphakathi lomzimba wombhede linikezwa ubambo oluqinisayo olumise okwe-W, okuqinisa kakhulu ukuqina kombhede womshini futhi kunciphisa ukuguqulwa ngenxa yokuthwala isisindo.

Ngemuva kokuguga kokukhishwa kombhede, kungasusa ukucindezeleka okusele ekubunjweni, futhi kunciphise ukukhululwa kokucindezeleka okusele ekucubunguleni nasekusetshenzisweni komshini.

Kunezimbobo ezitshekile nezinamatshe ngemuva kombhede ezisetshenziselwa ukukhipha ama-chip.I-chip, isipholile, amafutha okugcoba nokunye kukhishwa ngqo kuthreyi ye-chip.Ngakho-ke ukuhlanzwa kwe-chip kulula, futhi uketshezi olupholile lungaphinda lusetshenziswe kabusha

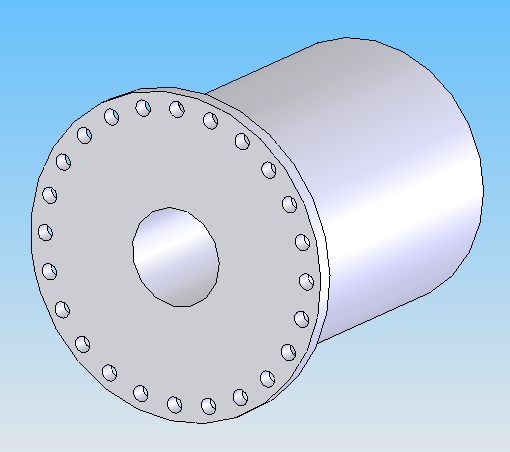

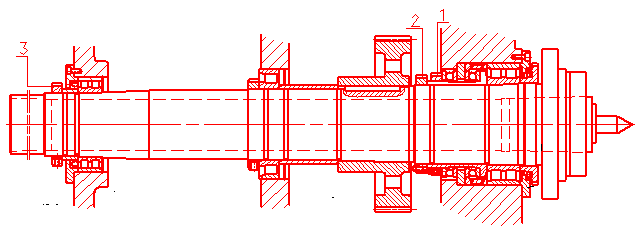

2)Ikhanda

I-spindle ithatha ukusekelwa kwamaphuzu amathathu, ingaphambili liyisiphetho esingaguquki, indawo ephakathi nangemuva iphetha njengesiphetho esihambayo, ingaphambili nangemuva ligcina njengesisekelo esiyinhloko, kanti phakathi nendawo njengesekelo elisizayo.I-axial positioning isethwe ekugcineni kwe-spindle, ukuze i-spindle iqhubekele emuva ngemva kokushiswa, isuse umthelela wesandiso esishisayo se-spindle ekunembeni kwethuluzi lomshini.

Idrayivu eyinhloko ye-lathe yenziwa yi-Siemens AC spindle motor ngokusebenzisa i-belt pulley, igiya kanye ne-4-stage hydraulic automatic shift.Uhla lwe-torque olungaguquki lwe-spindle lukhulu futhi ukusika isivinini esivamile kungabonakala.I-spindle beararing iyinhlangano ekhethekile, enembayo ephezulu kanye nokuqina okuqinile.

I-headstock igcotshwa ngamafutha aqinile, futhi amagiya we-headstock nama-bearings agcotshwa ngepompo ekhethekile yamafutha.Ingxenye engaphambili ye-spindle ithatha isakhiwo sokuvala kabili se-labyrinth ne-slot, esingavimbela ngempumelelo ukuvuza kukawoyela nezinto zangaphandle ukuthi zingangeni ku-headstock.

3): ithuluzi okuthunyelwe

Yamukela i-German SAUTER 8 isikhundla esivundlile i-turret engu-0.5.473.532.8, le turret inomsebenzi wokusika indilinga yangaphandle, ubuso bokuphela kanye nokulutha kanye nokugaya, ukubhola nokuthinta.Le turret ishayelwa yi-SIEMENS servo motor efakwe kuyo, futhi ihlanganiswe nezinto ezilandelayo.

| I-Ser.Cha. | Igama | Uhlobo | Qty |

| 1 | I-turret yamandla | 0.5.473.532.8 | 1 |

| 2 | Ikhanda lomsiki | 0.5.901.032/077790 | 1 |

| 3 | 0-degree isibambi sokusika amandla | 0.5.921.106-117859 | 1 |

| 4 | Isibambi sokusika amandla esingu-90-degree | 0.5.921.206-117866 | 1 |

| 5 | Isibambi sokusika isiyingi sangaphandle | B2-60X32X60-113908 | 2 |

| 6 | Isibambi sokusika isiyingi sangaphakathi | E2-60X50-113961 | 2 |

4)Z kanye ne-X eksisi:

Ububanzi besikulufu sebhola se-X axis isφ40x5, i-axis engu-Z ishayelwa i-rack negiya, imojuli yamazinyo ingu-m=5, kanye ne-axis engu-z isebenzisa isilawuli esigcwele seluphu esivaliwe ngokugreyitha impendulo yerula

5) Isitoko somsila

I-Tailstock iqukethe ingxenye engaphezulu nengxenye engezansi, inhlangano yokulungisa i-quill kanye ne-quill center ifakwe engxenyeni engenhla.Ukuhamba kwe-tailstock kuqhutshwa yi-motor.I-quill ye-tailstock ingajikeleza.

6)isistimu yokugcoba

Ukugcoba kwama-bearings ku-headstock, amagiya kanye ne-bearing in headstock namanye amacala kunikezwa iphampu ekhethekile, ukugcoba kwama-bearings of ball screw kanye nephuzu ngalinye lokugcoba lomshini lithatha ukuthambisa okuphakathi nendawo, futhi isikhathi sokugcoba siyalungiseka, ukuze kuvimbela ngempumelelo ukumosha uwoyela wokugcoba, futhi ingathuthukisa ngempumelelo impendulo eguquguqukayo yomshini kanye nempilo yesevisi yendlela yomhlahlandlela kanye nesikulufu sebhola.

uhlelo lwe-hydraulic

IHydraulic system isetshenziselwa ukushintsha okuzenzakalelayo kwejubane lokupholisa nokupholisa ngempoqo kwamagiya esitokisini kanye nokukhiya okuzenzakalelayo kwe-C axis.

7) I-eksisi ye-C

I-axis ye-C ishayelwa injini ye-servo, ingashintshela ngokuzenzakalela kumodi yokudlulisela ye-spindle kanye ne-C axis, ingemuva le-spindle lifakwe ngokunemba okuphezulu kwe-grating eyindilinga ye-axis ye-C kanye nendlela yokudambisa amabhuleki.Ngesistimu yokulinganisa iluphu evaliwe.

Ukunemba komshini

| Qedela ukusika indilinga yangaphandle | 0.005mm |

| Ukungaguquguquki komshini, ngobude obungu-300mm | 0.03mm |

| Ukucaba kokuqeda ukusika flat, | |

| ububanzi 300mm | 0.025mm, concave |

| I-X eksisi | |

| ukunemba kokubeka | X≤0.03mm |

| phinda ukunemba kokuma | X≤0.012mm |

| Z eksisi | |

| Ukunemba kokuma, kubude obungu-10000mm | X≤0.13mm |

| Phinda ukunemba kokuma | X≤0.05mm |

| I-C eksisi | |

| ukunemba kokubeka | 36” |

| phinda ukunemba kokuma | 18” |