Umshini wokugcwalisa umgodi ojulile we-TK2150

I. Ukusebenza kwenqubo eyisisekelo yomshini

1) Lo mshini ungasetshenziselwa ukugoqa izimbobo zangaphakathi.

I-2) Ngesikhathi somshini, i-workpiece iyajikeleza, ithuluzi lokusika liphakelayo, futhi Ukusika uketshezi kungena endaweni yokusika nge-trepanning bar ukuze kuphole futhi kugcobe indawo yokusika futhi kususe ama-chips ensimbi.

I-3) Lapho i-trepanning, ingemuva elingemuva le-trepanning bar lisetshenziselwa ukunikezwa kwamafutha, futhi ukuphela kwekhanda lokucindezela kwamafutha kusetshenziselwa ukusika.

6) Ukunemba kwemishini yethuluzi lomshini:

I-Trepanning: Ukunemba kwembobo IT9-10.Ubulukhuni bobuso: Ra6.3

Ukuqina kwezimbobo zomshini: ngaphansi kuka-0.1/1000mm

Ukuphambuka kokuphuma kwembobo yomshini: ngaphansi kuka-0.5/1000mm

II.Ipharamitha yobuchwepheshe eyinhloko

Ububanzi be-Trepanning……………………………φ200-φ300mm

Ubukhulu.ukujula kwe-trepanning …………………………… 6000mm

I-clamping diameter ye-workpiece………… φ200~φ500mm

Ibhore le-spindle ……………………………………… φ130mm

I-taper yangaphambili ye-spindle of headstock…… metric 140#

Ibanga lesivinini sophimbo ………………3.15~315r/min

Isivinini sokuphakelayo………………………… 5~1000mm/min, asinasinyathelo

Isivinini sokuhamba esisheshayo sehhashi……… 2000mm/min

Injini eyinhloko………… 30kW (i-asynchronous motor enezigaba ezintathu)

Injini yokuphakelayo……………………………N=7.5Kw (i-servo motor)

Injini yepompo ye-Hydraulic ………………… N=2.2kW,n=1440r/min

Injini yephampu epholile…N=7.5 kW (amasethi ama-2 wamaphampu ashumekiwe amaphakathi)

Ingcindezi elinganiselwe yesistimu yokupholisa ………0.5MPa

Ukugeleza kokupholisa …………………………………300,600L/min

Usayizi wawo wonke womshini …………1700mmⅹ1600mmⅹ1800mm

III.Ukusebenza nezici zomshini:

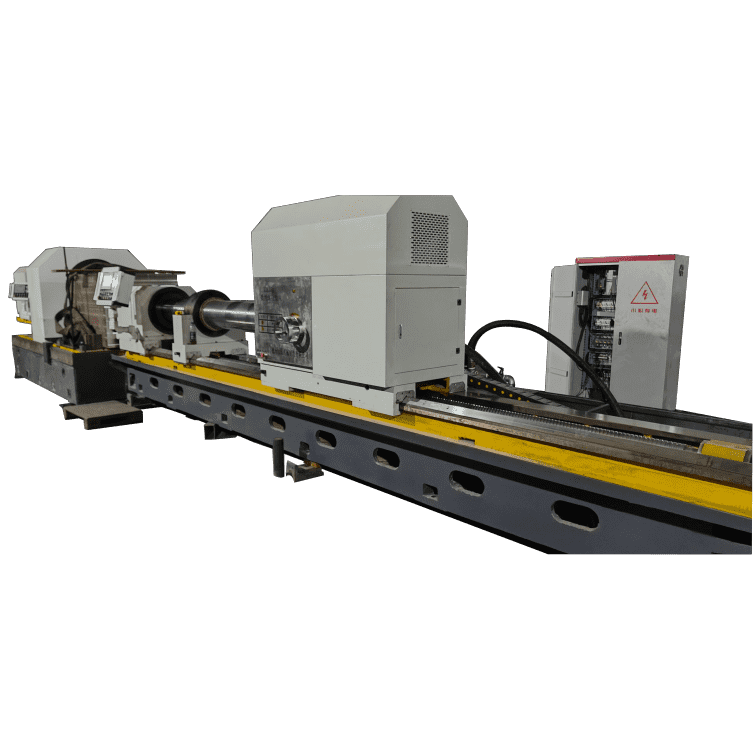

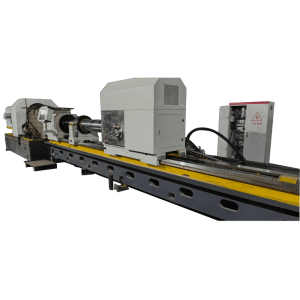

Umshini we-TK2150 CNC trepanning iyithuluzi lomshini elikhethekile lokucubungula izingxenye zembobo ejulile eyicylindrical.

Ngesikhathi senqubo ye-trepanning, okokupholisa kunikezwa kusukela ekugcineni kwebha ye-trepanning, futhi isiphetho sekhanda lomfutho kawoyela sifakwe isibani sokusika.Ifanele ukukhiqizwa ngobuningi futhi ingasetshenziselwa ucezu olulodwa kanye nokukhiqizwa kwenqwaba encane.

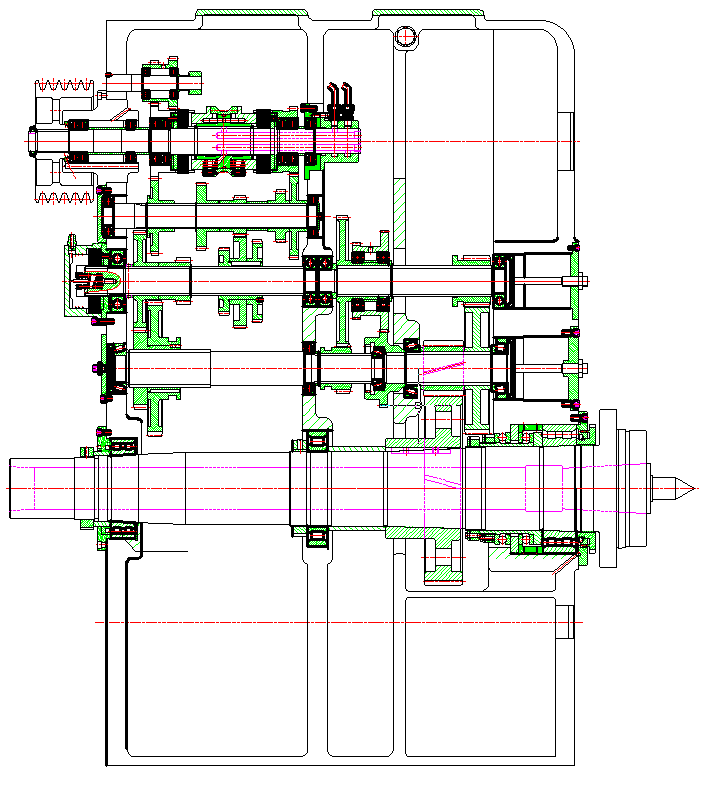

IV.isakhiwo main umshini

1) Ithuluzi lomshini lakhiwe izingxenye eziyinhloko ezifana nombhede, i-headstock, isihlalo sehhashi, isistimu yokuphakela isihlalo, ukuphumula okungaguquki, ukudlidliza okungaguquki kwe-trepanning bar, uhlelo lokupholisa, uhlelo lukagesi, idivayisi yokususa insimbi yensimbi, njll.

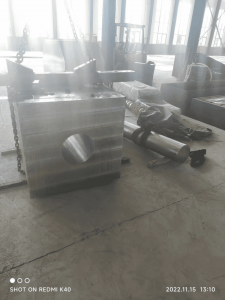

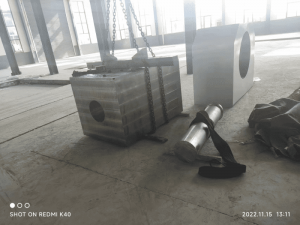

I-2) Umbhede, isihlalo sehhashi, isihlalo sehhashi, ibhokisi, ikhanda lokucindezela uwoyela, umsekeli nezinye izingxenye zonke zenziwe ngensimbi ephezulu yamandla kanye nesikhunta sesihlabathi se-resin, okuqinisekisa ukuqina okuhle, amandla, nokugcinwa ngokunemba kwethuluzi lomshini.Umbhede wamukela ukucishwa komsindo okuthuthukisiwe okuthuthukisiwe emhlabeni wonke, ngokujula kokucisha okungu-3-5mm kanye ne-HRC48-52, enokumelana nokugqokwa okuphezulu.

(1) Umbhede

Umbhede wethuluzi lomshini wakhiwe ngenhlanganisela yezingcezu ezintathu zemizimba yokulala.Umzimba wombhede uyisakhiwo esinezinhlangothi ezintathu ezivaliwe nezimbambo ezithambekile, futhi wenziwe ngensimbi ephonswe yekhwalithi ephezulu engu-HT300 enokuqina okuhle.Ububanzi besitimela somhlahlandlela wombhede ngu-800mm, okuyindlela eyisicaba kanye ne-V-guide enamandla okuthwala umthwalo ophezulu kanye nokunemba okuhle kokuqondisa.Indlela yomhlahlandlela ithole ukwelashwa kokucisha futhi inokumelana nokugqokwa okuphezulu.Emseleni wendlela yomhlahlandlela wombhede, kufakwa isikulufu sebhola lokuphakelayo, esisekelwa abakaki kuzo zombili iziphetho futhi sisizwa amafreyimu amabili okuhudula phakathi.Uhlaka lokuhudula lungahamba ngendlela yomhlahlandlela ezansi kwenkundla, futhi ukuhamba kwayo nokuma kulawulwa ipuleti lokudonsa namarola kusihlalo.Kukhona igroove emise okuka-T odongeni olungaphambili lombhede, olufakwe isihlalo sebanga eligxilile se-vibration damper esingaguquki ibha eyisicefe, kanye nesihlalo sehhashi lebanga eligxilile ukulawula ukuma kokudlidliza okungaguquki kwebha eyisicefe nesihlalo.Udonga lwangaphambili lombhede lufakwe ama-rack anamagiya edivayisi yezandla ukuze anyakazise ukuphumula okungaguquki, isisekeli, nesidambisi-msindo sokudlidliza esingaguquguquki sebha eyisicefe.

(2) Ikhanda:

Imi sekupheleni kombhede kwesokunxele, ibhore yokuphotha ingu-φ 130mm.I-headstock ishayelwa yinjini engu-30kW, kanti isivinini sokuphotha singu-3.15-315r/min ngokuncishiswa kwegiya elinezigaba eziningi kanye nokushintshwa kwamagiya aphezulu naphansi.Faka i-chuck yemihlathi emine ekugcineni kwe-spindle ukuze ubambe ucezu lomsebenzi.

I-headstock ifakwe uhlelo oluzimele lokugcoba ukuhlinzeka ngokugcobisa okuqinile kwama-bearings ahlukahlukene kanye nama-gear pair.

(3)Isihlalo sehhashi nekhanda lokuhamba

Inhloko yohambo igxilile kwisihlalo sehhashi, futhi ngesikhathi sokuphakela, inhloko yohambo (egxiliswe ngemuva kombhede) ishayela isikulufu ukuze sijikeleze, okubangela ukuthi inati elihlanganiswe nehhashi linyakaze nge-axially, lishayela isihlalo ukuze sondle.Lapho isihlalo sehhashi sihamba ngokushesha, injini esheshayo ngemuva kwesihlalo ishayela isinciphisi isivinini ukuze sizungeze, ishayela ihhashi ukuze ihambe ngokushesha.

Inhloko yohambo igxilile phezu kwesihlalo.Umsebenzi oyinhloko ukubopha ibha ye-trepanning futhi uyiqhubele phambili nangemuva ngokusebenzisa isihlalo.

(4)Ibhokisi lokuphakelayo

Ibhokisi lokuphakelayo lifakwa ekugcineni kombhede futhi lishayelwa yi-AC servo motor.I-axis yokukhipha ingafinyelela ukulawulwa kwesivinini esingenasinyathelo se-0.5-100r/min.Ukugcoba ngaphakathi kwebhokisi kunikezwa yiphampu ye-plunger eshayelwa ikhamera.Kukhona i-clutch yokuphepha ekuxhumekeni phakathi kwe-shaft ephumayo nesikulufu, futhi amandla okubandakanya angalungiswa yiziphethu.Uma ilayishwe kakhulu, i-clutch iyanqamuka futhi i-microswitch iculwa ukuthumela isignali yokumisa isihlalo (isikhombi sephutha sibonisiwe)

(5)Ukuphumula okuqinile kanye nojeke we-workpiece

Indawo yokuphumula engaguquki isebenzisa ama-roller amathathu afakwe ama-rolling bearings njengokwesekwa kwendawo yokusebenza.Ama-roller amabili aphansi abekwe kubakaki, futhi ubakaki uhamba endleleni yokuqondisa ukuze usekele umsebenzi wokusebenza.Abakaki bangaphambili nabangemuva banganyakaziswa ngesikulufu sebhola, kuyilapho i-roller engenhla ifakwe phezu kwenduku yomhlahlandlela, ehamba eduze kwembobo yomhlahlandlela.Ngemva kokuqedwa kokusekelwa, induku yomhlahlandlela idinga ukulungiswa ngezikulufo.

I-jack ifakwe ama-roller amabili anama-rolling bearing njengendawo yokusebenza.Ama-roller abekwe ku-jack, futhi i-jack ihamba endleleni yokuqondisa ukuze isekele umsebenzi wokusebenza.Amajekhi angaphambili nangemuva anganyakaziswa kanyekanye ngezikulufu zokuhola ezinhle nezingezinhle, futhi ukuqondanisa kwamarola amabili kungalungiswa ngomkhono wokulungisa wangaphambili.Ngemva kokusekelwa, kokubili ojeke kanye nenduku yokuqondisa kudingeka kulungiswe ngezikulufo.

(6)I-vibration damper engaguquki ye-trepanning bar:

I-vibration damper engaguquki isetshenziswa njengesisekeli sebha ye-trepanning.Ukuze uthole ama-trepanning bar azacile, kuyadingeka ukwandisa inani lokuzinza ngendlela efanele.Ukuhamba kwayo endleleni yomhlahlandlela wombhede ishayelwa inqola noma ingashayelwa nomshini osebenza ngesandla.Leli thuluzi lomshini lifakwe isethi yesidambisi manzi esinyakazayo se-trepanning bar.

(7)Isistimu yokupholisa:

Isistimu yokupholisa itholakala ngemuva kwethuluzi lomshini, ikakhulukazi elihlanganisa ithangi likawoyela, isiteshi sokumpompa, ipayipi likawoyela, inqola yokugcina ama-chip, kanye nomsele obuya uwoyela.Umsebenzi wesipholisi ukupholisa nokukhipha ama-metal chips.