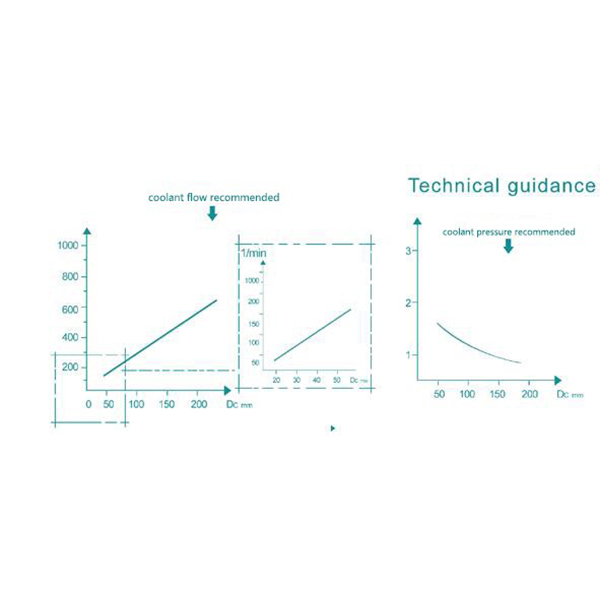

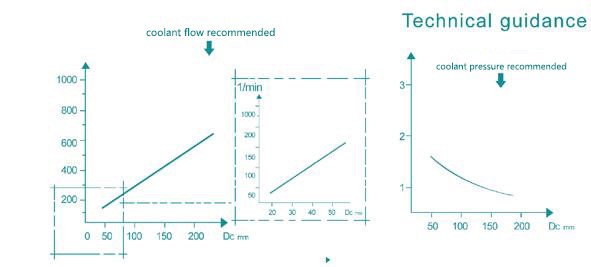

Isiqondiso sobuchwepheshe

Isiqondiso sobuchwepheshe

Imingcele yokusika ingeyereferensi kuphela futhi ilungiswe ngokuya ngezimo zangempela zokucubungula.Uma kuqhathaniswa ne-lotion ehlanganisiwe, amafutha ahlanzekile angathuthukisa impilo yesevisi yethuluzi.

Izinkinga nezixazululo

| SN | inkinga | isizathu | Isixazululo |

| 1 | Ama-chips ensimbi aphukile mancane kakhulu | Ipharamitha yokusika engalungile | Lungisa isivinini sokusika kanye nokudla |

| I-chip ephukile iwuhlobo lwe-groove olungalungile, futhi i-engeli eyi-elliptical incane kakhulu noma ijulile kakhulu | Shintsha uhlobo lwe-groove lwe-chip ephukile | ||

| Impahla yokusebenza ayizinzile | Lungisa isivinini esifanele kanye nokuphakelayo | ||

| Ukusika okungalungile kokuqala (i-workpiece ayigxili) | Ukumisa i-workpiece | ||

| 2 | Ama-chips ensimbi aphukile mancane kakhulu | Ipharamitha yokusika engalungile | Lungisa isivinini sokusika kanye nokudla |

| I-chip ephukile iwuhlobo lwe-groove olungalungile, futhi i-engeli eyi-elliptical incane kakhulu noma ayishoni kakhulu | Shintsha uhlobo lwe-groove lwe-chip ephukile | ||

| 3 | Ama-chips ensimbi aphukile awazinzile | Impahla yokusebenza ayizinzile | Lungisa ijubane lokusika kanye nokudla, shintsha uhlobo lwe-groove lwama-chips |

| Imodi yokuphakelayo engalungile (isb, i-hydraulic feed mod) | Xhumana nomenzi womshini noma unjiniyela wokuthengisa | ||

| ukupholisa okunganele kuholela ekuvaleni kokukhishwa kwe-chip | Khulisa ukupholisa | ||

| Ukudlidliza okuqinile okubangelwa ukuqina okunganele kocezu lokusebenza nethuluzi | Xhumana nomenzi womshini noma unjiniyela wokuthengisa | ||

| 4 | I-fibrous metal chips | Impahla yokusebenza ayizinzile | Lungisa ijubane lokusika kanye nokudla, shintsha uhlobo lwe-groove lwama-chips |

| Imodi yokuphakelayo engalungile (isb, i-hydraulic feed mod) | Xhumana nomenzi womshini noma unjiniyela wokuthengisa | ||

| Isipholile singcolile | Isipholile esicacile | ||

| Ukusabela kokuhlangana kwamakhemikhali phakathi kocezu lokusebenza nethuluzi le-carbide likasimende | Hlola bese ushintsha uhlobo lwethuluzi | ||

| Ukusika onqenqemeni | Faka esikhundleni sekhanda lokufaka noma lokubhoboza | ||

| Isivinini sokuphakelayo siphansi kakhulu | Khulisa isivinini sokuphakelayo | ||

| 5 | I-carbide enosimende ephukile | Ithuluzi lokusika libuthuntu kakhulu | Faka esikhundleni sekhanda lokufaka noma lokubhoboza |

| Isipholile esinganele | Hlola ukugeleza kokupholisa kanye nokucindezela | ||

| Isipholile singcolile | Isipholile esicacile | ||

| Ukubekezelelwa komkhono womhlahlandlela kuncane kakhulu | Shintsha umkhono womhlahlandlela uma kunesidingo | ||

| I-Eccentric phakathi kwenduku yokubhola kanye ne-spindle | Lungisa i-eccentric | ||

| Ipharamitha engalungile yokufaka | Shintsha ipharamitha yokufaka | ||

| Impahla yokusebenza ayizinzile | Lungisa isivinini esifanele kanye nokuphakelayo | ||

| 6 | Impilo yamathuluzi ifinyeziwe | Isivinini sokuphakelayo noma ukuzungezisa asaziwa | Lungisa okuphakelayo kanye nesivinini sokuzungezisa |

| Ibanga elingafanelekile le-alloy eqinile noma ukunamathela | Khetha i-alloy grade efanelekile njengempahla ngayinye yokusebenza | ||

| Isipholile esinganele | Hlola izinga lokushisa lokupholisa kanye nesistimu yokupholisa | ||

| Ukupholisa okungalungile | Faka esikhundleni sokupholisa uma kudingeka | ||

| I-Eccentric phakathi kwenduku yokubhola kanye ne-spindle | Lungisa i-eccentric | ||

| Ipharamitha engalungile yokufaka | Shintsha ipharamitha yokufaka | ||

| Impahla yokusebenza ayizinzile | Lungisa isivinini esifanele kanye nokuphakelayo | ||

| 7 | Ubulukhuni obuphezulu bendawo | i-eccentric | Hlola futhi ulungise |

| I-chip breaking groove inkulu kakhulu noma iphansi kunomugqa omaphakathi | Khetha i-chip breaking groove efanele | ||

| Usayizi ongalungile wethuluzi noma iphedi yomhlahlandlela | Khetha ithuluzi elilungile | ||

| I-Eccentric phakathi kwe-workpiece nekhanda lokumba | Lungisa i-eccentric | ||

| Ukudlidliza okuqinile | Bheka umenzi womshini noma ulungise ipharamitha yokusika | ||

| Ipharamitha engalungile yokufaka | Shintsha ipharamitha yokufaka | ||

| Isivinini sokusika siphansi kakhulu | Khulisa isivinini sokusika | ||

| Isivinini sokuphakelayo siphansi kakhulu ngesikhathi somshini wokusebenza oqinile | Khulisa isivinini sokuphakelayo | ||

| Okuphakelayo akuzinzile | Thuthukisa ukwakheka kokuphakelayo | ||

| 8 | I-Eccentric | Ukuchezuka kwe-workpiece kusuka esikhungweni somshini womshini kukhulu kakhulu | Lungisa futhi |

| Induku yokubhoboza yinde kakhulu, umugqa awulungile | Lungisa futhi | ||

| Ukugqokwa kwephedi yokufaka neyomhlahlandlela | Shintsha okufakiwe noma ezinye izingxenye | ||

| Isizathu sempahla yokusebenza (isici, ubulukhuni nokungcola njll.) | Khetha ithuluzi elifanele kanye nepharamitha yokusika | ||

| 9 | Isikulufa imbobo | Unqenqema lokufaka lwangaphandle luphukile | Faka esikhundleni |

| Iphedi likamhlahlandlela ligqokile noma ukusekela akwanele | Faka esikhundleni noma ulungise | ||

| I-centering eccentricity eyeqile yomshini nomsebenzi wokusebenza | Lungisa futhi | ||

| Ukupholisa nokuthambisa akwanele | Lungisa isakhiwo esipholile nesipholile | ||

| I-Cutting Edge ayibuthuntu kakhulu | Faka esikhundleni | ||

| Ipharamitha yokusika engalungile | Lungisa ipharamitha | ||

| Ukuqina namandla okuphakelayo akwanele | Lungisa umshini noma unciphise ububanzi bokubhola | ||

| 10 | Ukudlidliza kukhulu kakhulu phakathi nokucubungula | I-Cutting Edge ayibuthuntu kakhulu | Faka esikhundleni |

| Ipharamitha yokusika engalungile | Lungisa ipharamitha | ||

| Ukuqina komshini noma amandla okuphakelayo akwanele | Lungisa umshini noma unciphise ububanzi bokubhola |